The Karachaganak Field

This week’s analogue spotlight demonstrates how good reservoir management rejuvenated one of the world’s largest gas-condensate fields.

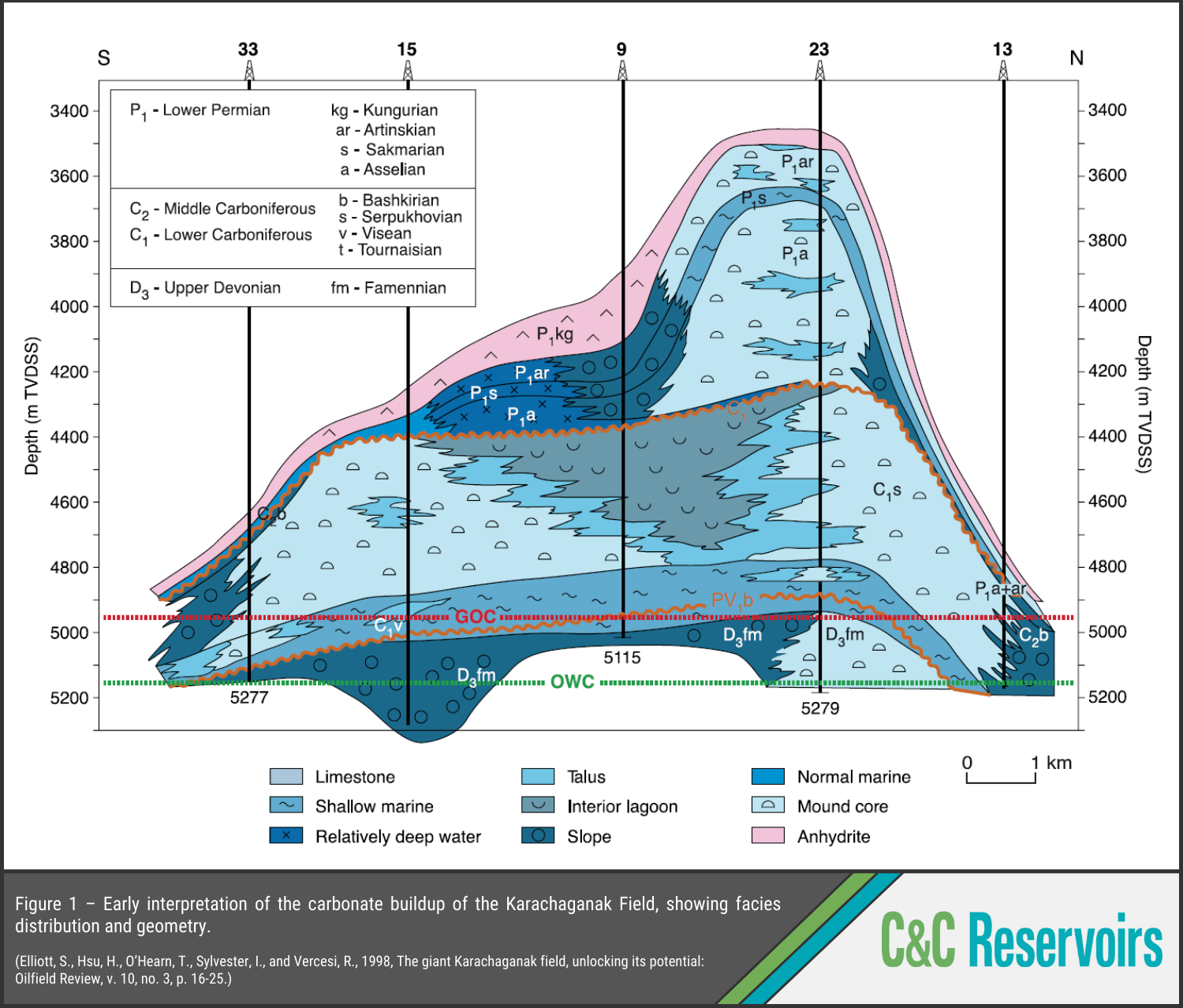

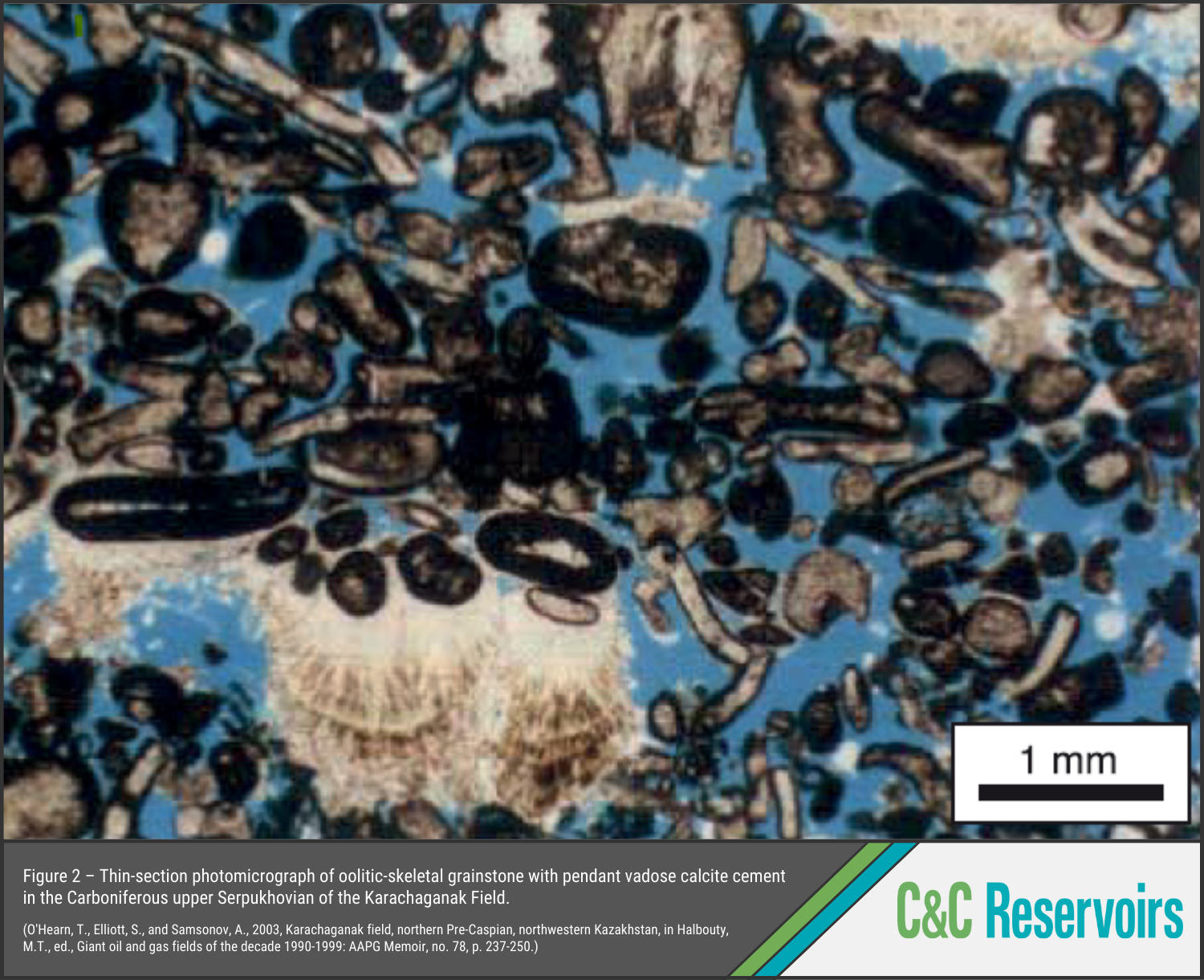

At the Karachaganak Field in Kazakhstan, up to 1800 m of limestone, dolomite and shale accumulated between the Late Devonian and Early Permian in environments that evolved from a carbonate ramp to biohermal mounds and pinnacle reefs (Figures 1 and 2). The reservoir contained in-place reserves of 8.4 BBC and 48.7 TCF in a formidable 1550 m gas-condensate column. A 215 m-thick oil rim contained 4.7 BBO of STOIIP.

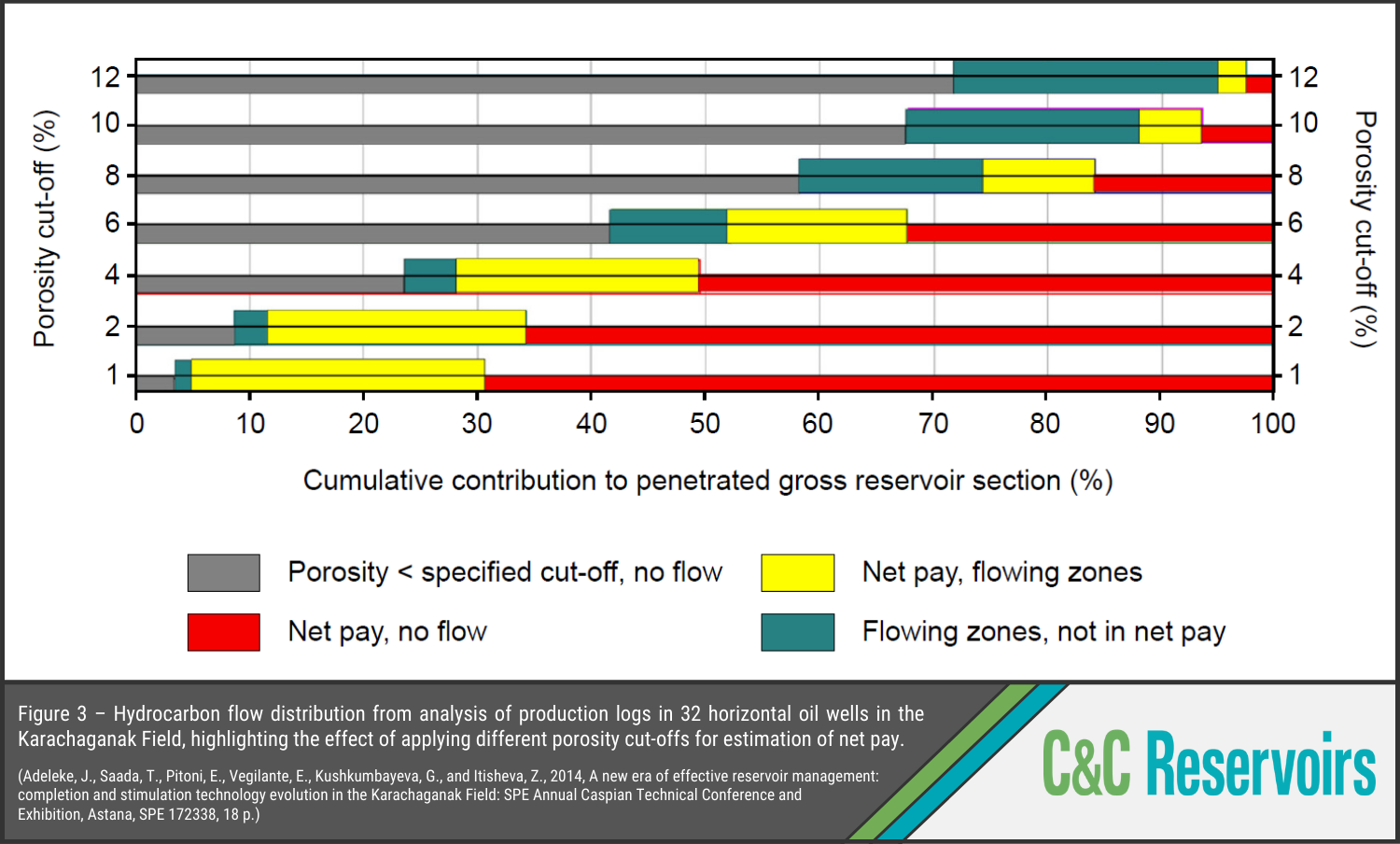

As a consequence of the complex depositional setting and diagenetic history, there is a wide range of permeability for a given porosity, so reservoir cut-off values are hard to define. No matter how the reservoir is defined, the combination of fractures, karst, anhydrite cement and dolomitization causes some non-reservoir intervals to produce while not all net intervals do (Figure 3). Average porosity is 7.5-9.2% and permeability ranges from 0.001 mD to >14 D, averaging 5-15 mD. Faults are locally sealing and divide the field into six blocks. Sequence boundaries and cemented layers form vertical permeability barriers.

Karachaganak came onstream in 1984. Condensate production was the initial priority, so few wells penetrated the oil rim. Production rose to 80,205 BCPD in 1991 and then declined to 30,785 BCPD by 1994 due to a lack of funds for further development and insufficient natural drive – particularly aquifer drive. Neglected wells scaled up and suffered severe corrosion. A workover programme that began in 1995 reversed this decline. Horizontal wells were used from 1997 to drain multiple isolated compartments simultaneously and for dedicated production from the oil rim starting in 2000. Gas re-injection from 2003 mitigated both pressure depletion and gas processing bottlenecks.

Acid washes were crucial but rarely treated entire horizontal sections. This changed in 2009 when multi-stage acid fracturing allowed treatments to be placed evenly along the wellbore or to target low-GOR intervals to curb excessive gas production. By 2017, these measures had increased production to 99,342 BOPD, 1416 MMCF/day and 242,000 BCPD. The field is on track for oil, gas and condensate recovery factors of 26%, 61% and 35%, respectively.

The Digital Analogue Knowledge System (DAKS™) contains many global oil and gas analogues specifically focused on carbonate reservoirs. Use these analogues to benchmark your own field, and delve into C&C Reservoirs Reservoir Evaluation Reports to discover best practices from top performing reservoirs that can be applied to your own assets.