The Ghawar Field

This week’s Analogue Spotlight is the Ghawar Field in Saudi Arabia. This super-giant field demonstrates how fractures can complicate production from a porous, permeable carbonate reservoir with an otherwise simple structure.

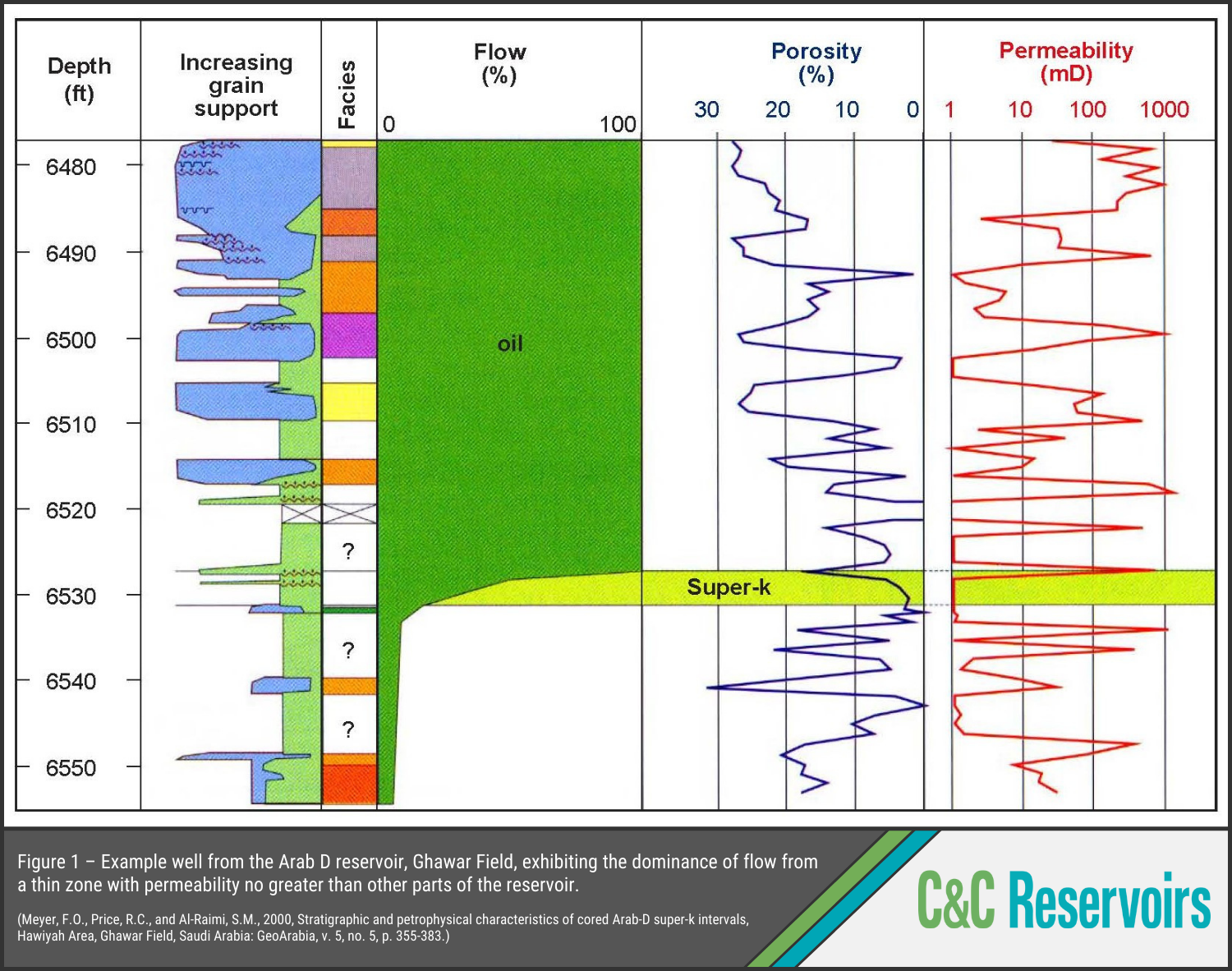

With a STOIIP of 162 BBO, Ghawar is by far the largest conventional oil field in the world. However, size does not guarantee success. The Arab D reservoir comprises a highly permeable zone of dolomitised grainstones and packstones with tight hardgrounds, overlying a low-permeability zone of wackestones and mudstones with numerous high-permeability layers. The hardgrounds and permeable layers intersect beds at a low angle to divert layer-parallel flow paths. Production logs show that thin (0.5 ft) layers provide a disproportionately large share of the total oil influx in many wells. These ‘super-k’ zones neither correspond to a particular lithology nor even to high-permeability layers, sustaining for many years high flow rates that would not be supported by their measured core permeability (Fig. 1).

The weak natural drive was supplemented by dump-flood peripheral water injection from 1966, followed by pressurised seawater injection from 1973. Together, they boosted production to >5 MMBO/day by 1974. Water injection was effective but the super-k zones caused irregular sweep and early water breakthrough. Many of the affected producers were shut in. It was suspected that fractures were responsible so the image logs were re-examined, revealing a pervasive network of vertical open fractures connected to and responsible for the super-k zones.

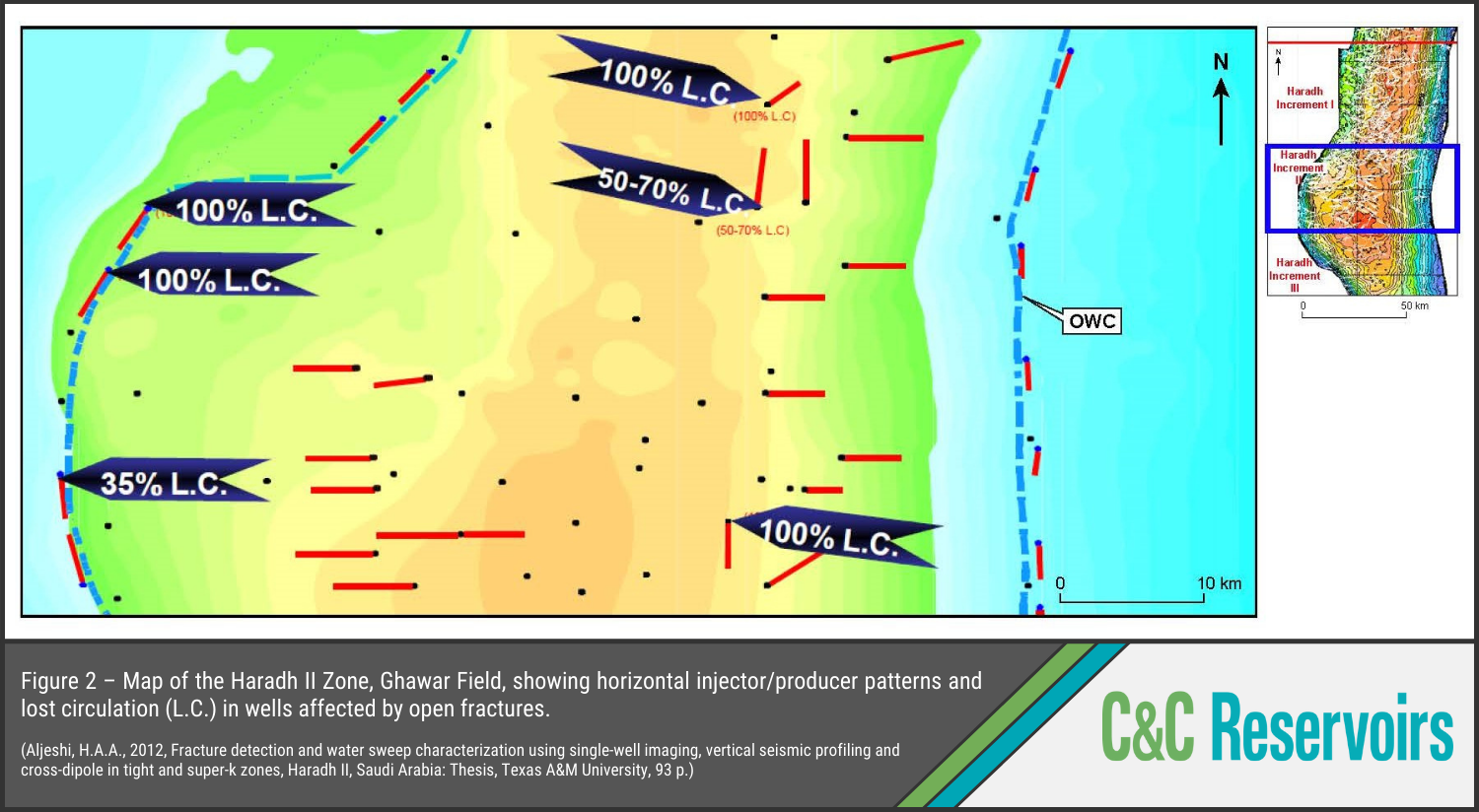

In the 1990s, 3-D seismic reservoir characterisation and horizontal wells came to the rescue. New models could predict fracture distribution and enabled multilateral horizontal producers to be placed parallel to fracture planes to avoid intersecting them, while horizontal injectors deliberately intersected them to maximise pressure support (Fig. 2). The new wells had reservoir sections >5 km and were fitted with chokes to isolate watered-out laterals. They were twice as productive as their vertical counterparts, helping to maintain production at nearly 5 MMBO/day between 1991-2003. Analysis in DAKS shows that Ghawar’s 55% ultimate recovery factor is greater than that of 92% of carbonate oil reservoirs worldwide.

The Digital Analogue Knowledge System (DAKS™) contains many global oil and gas analogues specifically focused on heavy oil fields. Use these analogues to benchmark your own field, and delve into C&C Reservoirs Reservoir Evaluation Reports to discover best practices from top performing reservoirs that can be applied to your own assets.