C&C Reservoirs recently presented at the UK’s Oil and Gas Authority EOR Workshop in Aberdeen. The presentation described how C&C Reservoirs’ new EOR knowledge base and analytics tools are of value to governments and E&P companies seeking to maximise economic oil recovery from their assets.

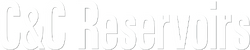

Figure 1 – DAKS™ EOR documents the key learnings from the global application of serval EOR processes.

The UK challenge of maximising economic oil recovery

In 2014 a UK Government Report (The Wood Review) outlined how the UK should Maximise Economic Oil Recovery (MERUK). Within the important role played by EOR was highlighted and this led to the creation of a UK Pilot EOR Workgroup. The purpose of this workgroup was to identify EOR knowledge application opportunities through a screening of all UK oil fields. The Pilot EOR work identified a significant potential for EOR knowledge application.

Subsequently in 2016 the UK’s Oil and Gas Authority developed an EOR Strategy and Delivery Programme to progress opportunities. The Aim of the OGA’s EOR Strategy and EOR Delivery Programme was to:

-

Introduce early EOR screening for regulatory approval Field Development Plans (FDP).

- EOR screening is part of the regulatory approval process in FDP.

- An obligation for operators to justify why EOR is not being used.

- Ensure that in preparation of FDPs, the appropriate level of EOR modelling/screening has been completed and future EOR forecasts presented.

-

Promote the progression of high-graded EOR resource opportunities.

- Ensure operators maximise EOR benefits and economics.

- Identify barriers to deployment and help provide mitigations.

- Support and encourage EOR in heavy oil fields.

In addition, the UK’s OGA Asset Stewardship Expectations encourage the assessment of EOR. In consultation with the industry, the OGA has developed stewardship expectations across the oil and gas lifecycle, for operators and licensees. Companies must understand the recovery technical limit and current predicted recovery, and then evaluate and select future recovery options (new wells, improved oil recovery, enhanced oil recovery) to maximise economic recovery. They must also identify the associated technology and/or production strategies required to maximise economic recovery.

C&C Reservoirs Support for EOR Screening and Application

C&C Reservoirs can support governments and E&P companies to maximise economic oil recovery from their reservoirs through the new EOR studies.

The aim of the DAKS R&D project is to create an EOR knowledge base based on the proven application of EOR processes. The focus will be on all deployed EOR processes at field, reservoir, pilot or well level. Reports will focus on projects that have proven to be effective “Evidence of Success”. Each report will document the impact of the EOR processes on production performance to identify the best EOR processes for each reservoir type.

The Applications

- Screen and identify relevant EOR processes.

- Quickly evaluate the application for full or partial deployment.

- Test the key EOR success factors based on the reservoir characteristics.

- Benchmark EOR performance against relevant global analogues.

- Forecast potential incremental recovery from each EOR method.

- Validate viable EOR methods for specific reservoir properties.

The Features

- Creation of a comprehensive set of EOR Reports & digital Tables of Parameters (ToP).

- Benchmarking and analysis tools to isolate why EOR techniques have been successful.

- EOR screening tools to quickly identify if and which EOR techniques are relevant.

- Integrate into DAKS portfolio tools for decision making at the asset & corporate level.

The Benefits

- Save time in documenting global EOR projects and identify successes.

- Quickly and efficiently evaluate the entire range of EOR knowledge options.

- Applicable to all reservoir types from dual porosity naturally fractured carbonate systems to homogeneous sandstones.

- A consistent analogue workflow based on a common classification system that ensures relevant analogues are being considered for screening, validation, benchmarking and forecasting.

- Satisfy SPE and SEC reserves booking guidelines which require analogue identification and benchmarking.

- Save time and money over detailed modelling by narrowing EOR options before reservoir simulation.

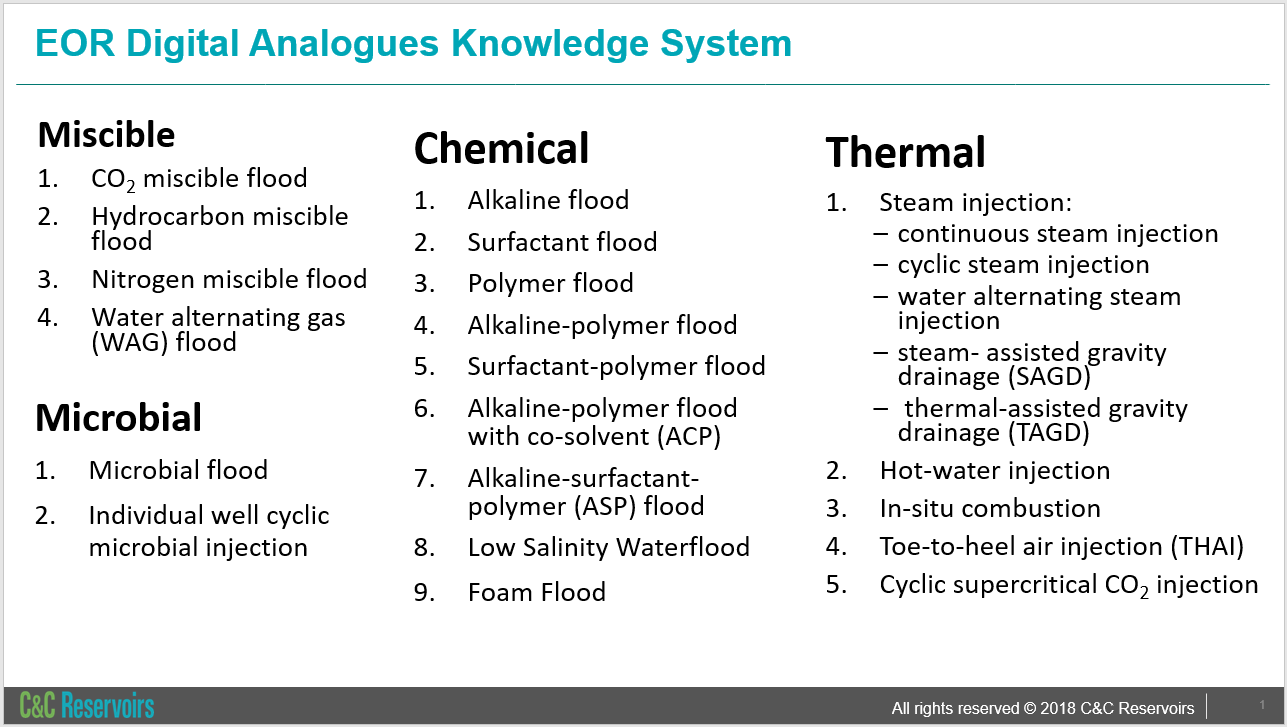

Figure 2 – Global Application of EOR from DAKS.

Polymer EOR was a key focus of the OGA EOR Strategy

One of the key EOR technologies seen as important for the UKCS was Polymer EOR and through 2017 several major oil companies (BP, Chevron, Shell and Equinor) worked with the OGA to develop a document to support companies who are appraising Polymer EOR in the UK. UK data estimated recovery factor for the 10 UKCS offshore polymer projects ranged from 1% to 11%. Studies conducted in the USA display a larger range and upside in incremental recovery factors. This can be attributed to UKCS offshore operating environment, wider well spacing, increased polymer supply costs all play a role in impacting the potential polymer EOR prize.

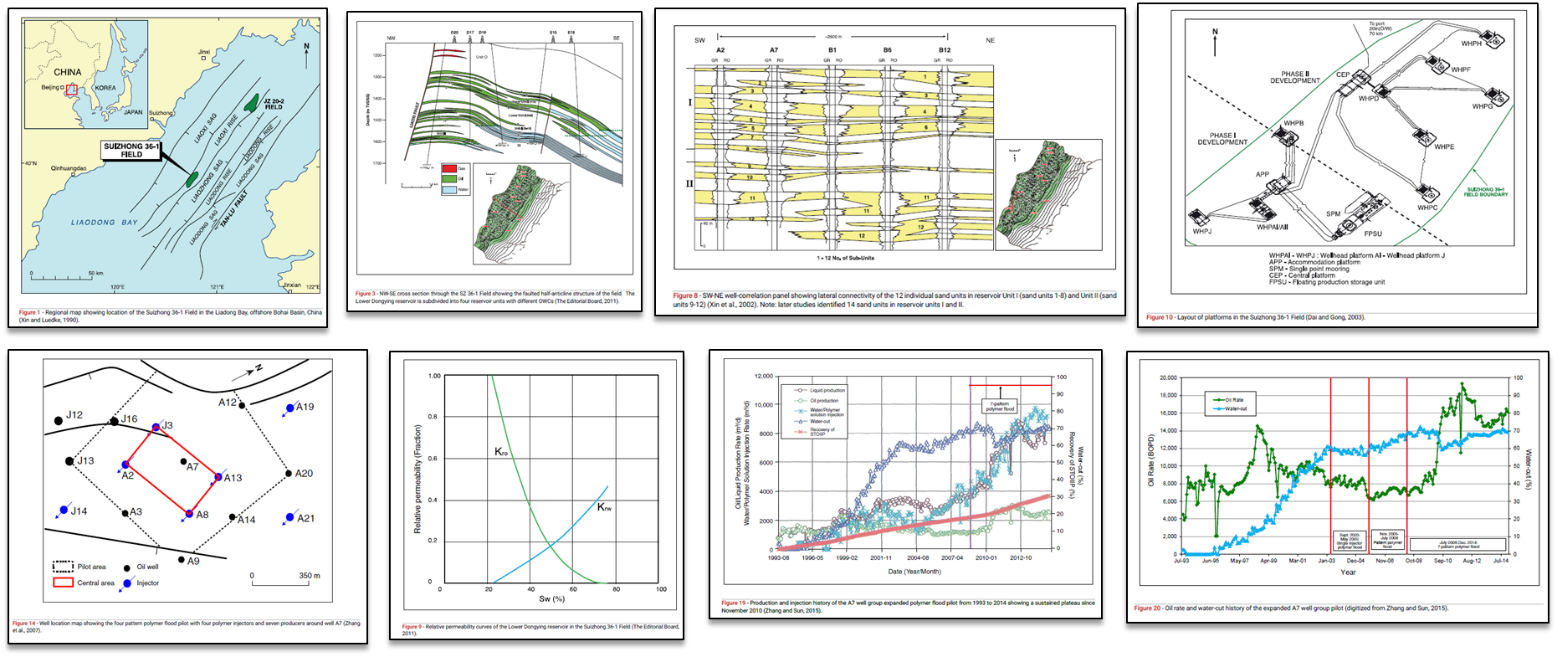

C&C Reservoir studies have identified several global analogues for Offshore Polymer EOR projects. One example is the Chinese Suizhong 36-1 offshore polymer flood. Lessons learned from these Polymer Projects can increase confidence in UKCS Polymer EOR applications. A summary of the EOR report is given below together with a snapshot of the report information that can be obtained from C&C Reservoirs as an example of the report information being compiled.

- An offshore viscous sandstone reservoir oil field.

- Starting polymer flood at low water-cut stage achieving both efficient waterflood and excellent polymer flood.

- Experienced single well injecting pilot, 4-pattern pilot and field-wide polymer flood.

- Adopting a fit-for-purpose hydrophobically associating water-soluble polymer (HAWP).

- Utilizing skid-mounted, modular polymer dispersion and injection facilities.

- Incremental recovery of 8.4%.

Figure 3 – Example Chinese Suizhong 36-1 offshore polymer flood (Figures)