The Tupi Field

Analogue Spotlight

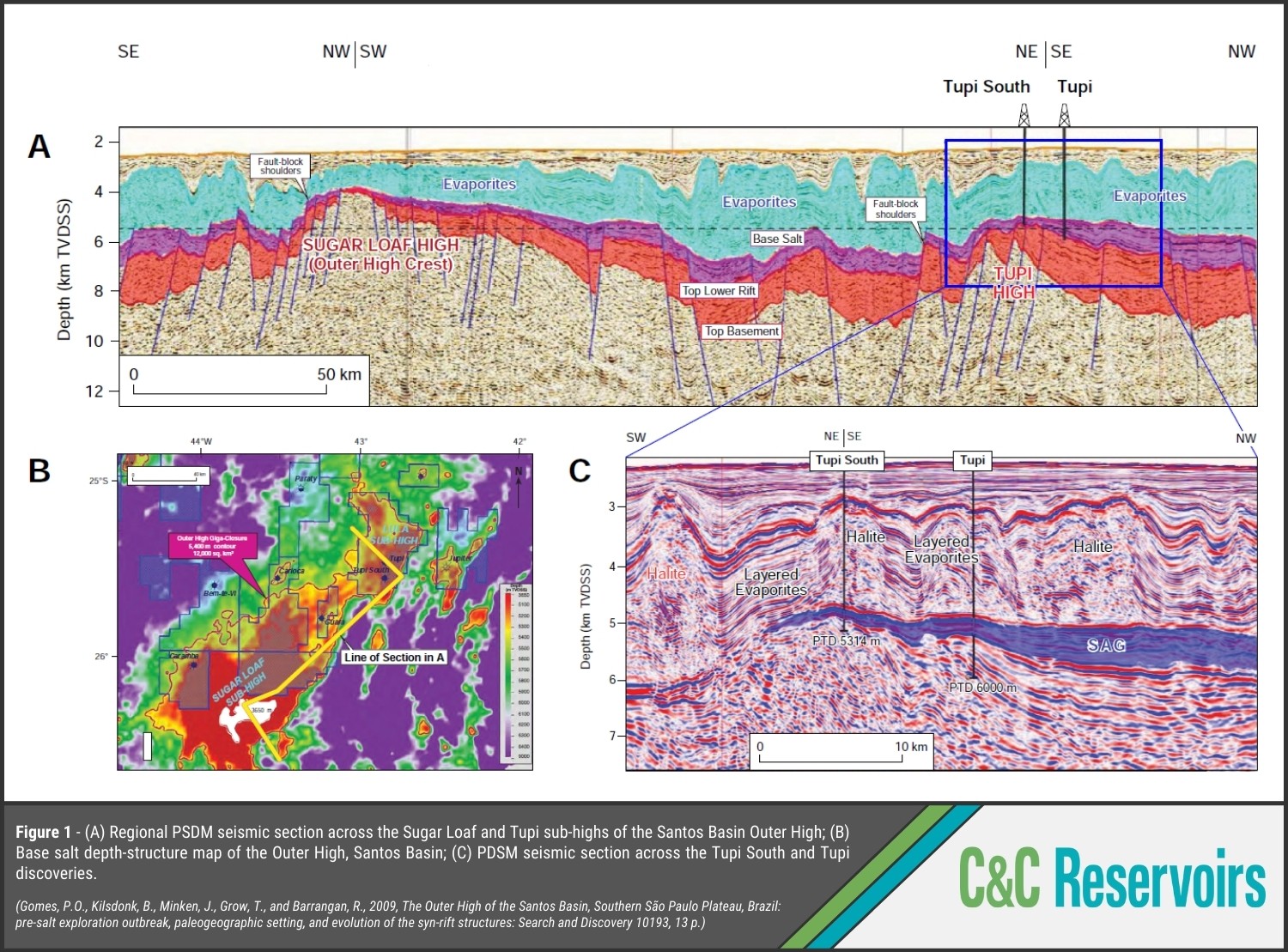

Located in deep water (>2100 m), 160 miles off the coast of Brazil, the Tupi Feld is one of the largest oil discoveries in the last 30 years. Tupi sits in a pre-salt tilted fault block (Fig. 1) and boasts a STOIIP of 22,280 MMBO, however, extracting these resources comes with significant technical challenges.

Beyond the challenges presented by water depth greater than 2000 m, Tupi contains paraffinic oil and exhibits a high GOR of 1206-1472 SCF/STB, 8-12% of which is CO2. This creates operational complexities, including wax and asphaltene precipitation and a corrosive environment. Additionally, the reservoir is sealed by 2 km of evaporites, raising major concerns over casing failure due to salt creep.

To address these issues, several measures were introduced:

- Downhole chemical injection lines and thermal insulation were installed to control scaling, wax and asphaltene precipitation.

- Corrosion resistant alloys in subsea lines and topside piping were incorporated to counter the effects of CO2 corrosion.

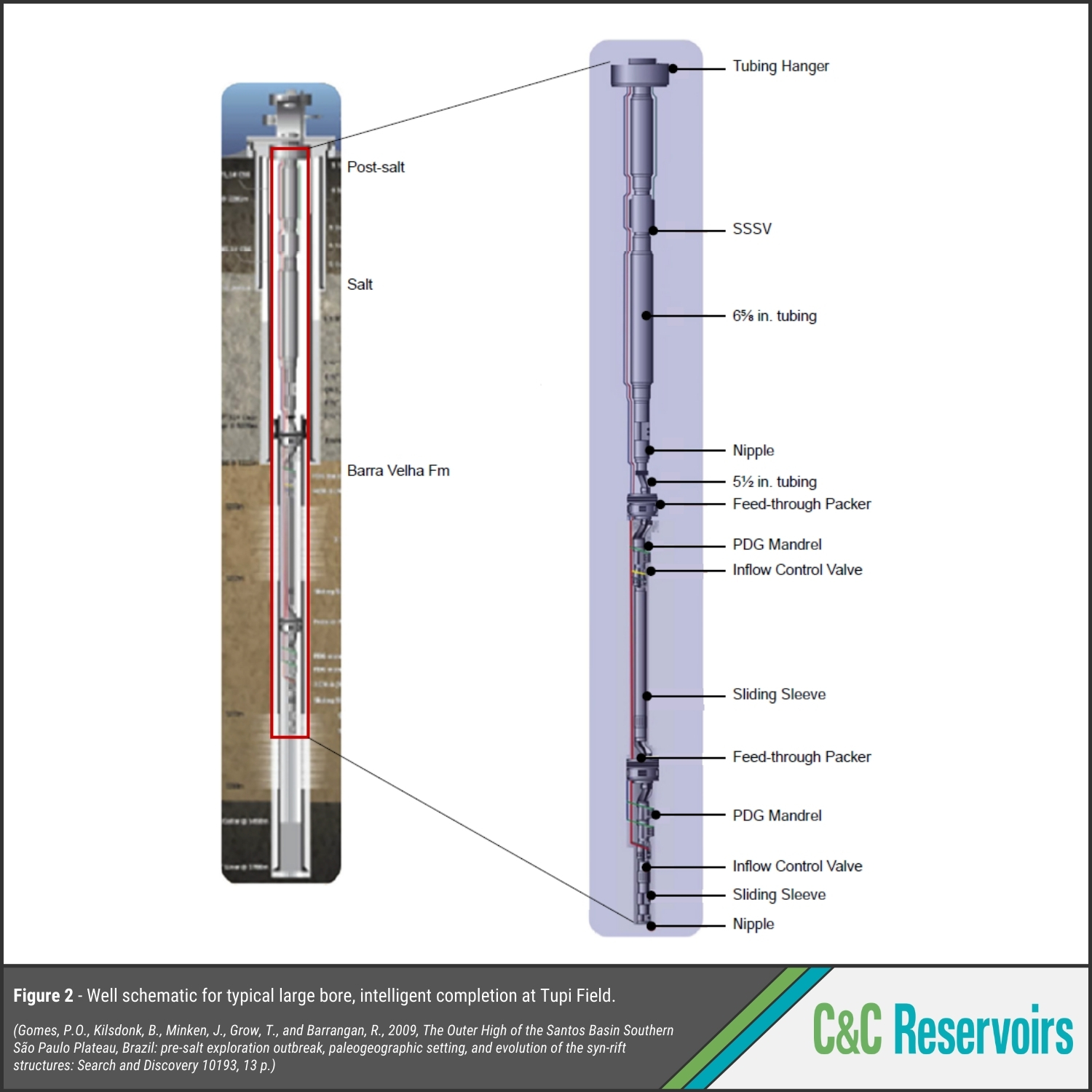

- Intelligent dual-zone completions and interval control valves were used to manage rising water cut and GOR while enabling temporary gas shut off (Fig. 2). Excess gas is then reinjected into the reservoir as part of a CO2 WAG miscible flood to enhance recovery.

- Rigorous wellbore planning and executed with tight controls on calliper, tortuosity and mud chemistry to prevent wellbore enlargement that would otherwise leave casing susceptible to bending and flattening from salt flow.

- Managed pressure drilling was employed to minimize loss of circulation, further ensuring well integrity.