The Prudhoe Bay Field

Analogue Spotlight

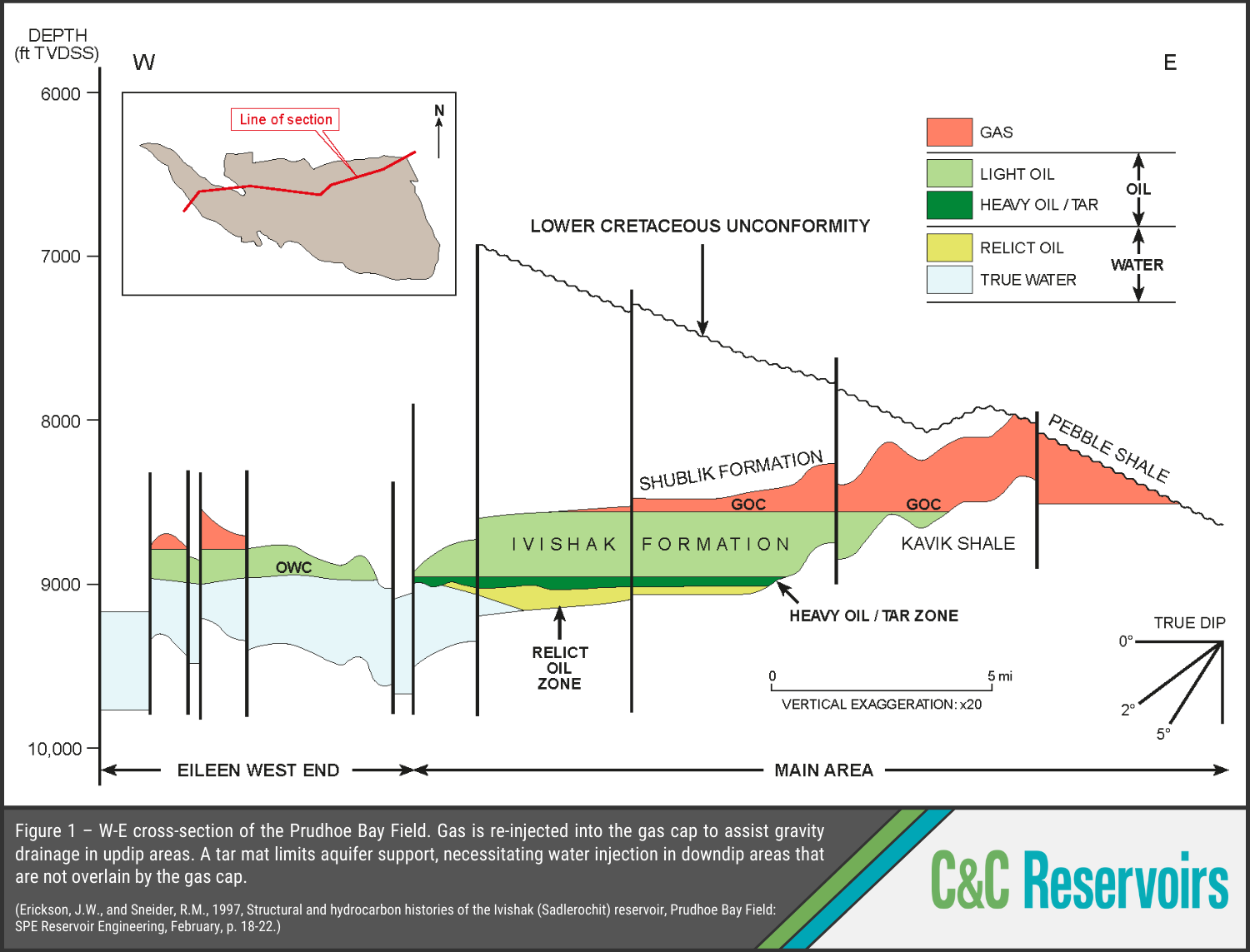

Buried 8000 ft beneath the eponymous Alaskan inlet, the supergiant Prudhoe Bay Field contains 25 BBO and 46 TCF in Triassic braided-river and deltaic reservoirs of the Ivishak Formation (Fig. 1). With recoverable reserves of 13 BBO and 24 TCF, the Ivishak reservoir at Prudhoe Bay has an ultimate oil recovery factor of 52%. That is greater than 81% of 165 onshore, braided-river/deltaic sandstone oil reservoirs in DAKS that are also complicated by macro-scale faults and shale layers. We explore one aspect of Prudhoe Bay’s success – miscible gas injection.

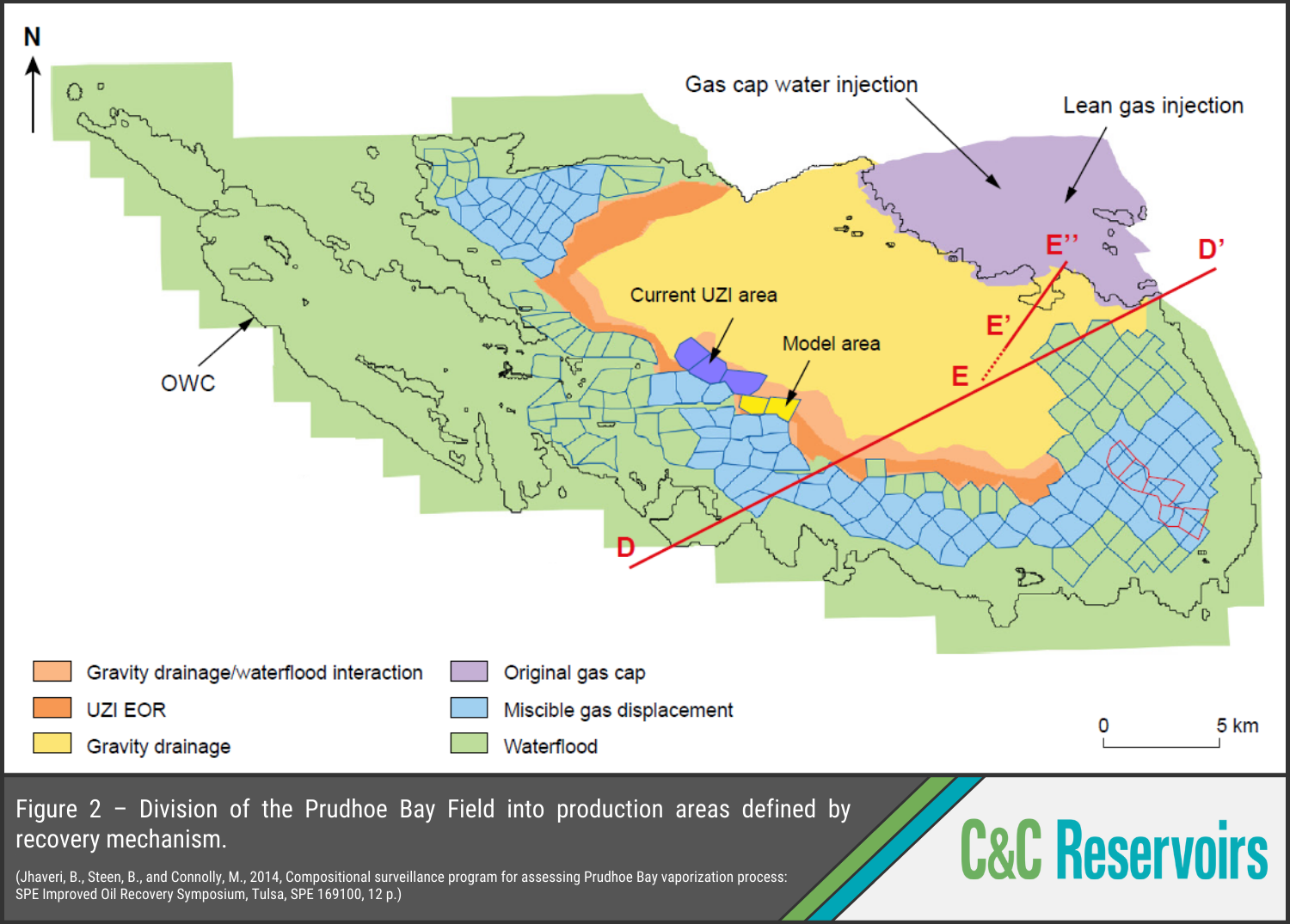

Produced gas has been re-injected into the gas cap from the outset to assist gravity drainage in updip areas while waterflooding has targeted downdip areas not overlain by the gas cap, where the natural drive was weak. It was recognized early on that the gas recycling plant was a ready source of miscible injectant (MI) so starting in 1982 with an 11-pattern pilot, water/miscible gas injection was gradually rolled out across the field (Fig. 2). By 2014, 3.4 TCF of MI had been injected into 200 patterns and the technique had recovered an incremental 8% of STOIIP.

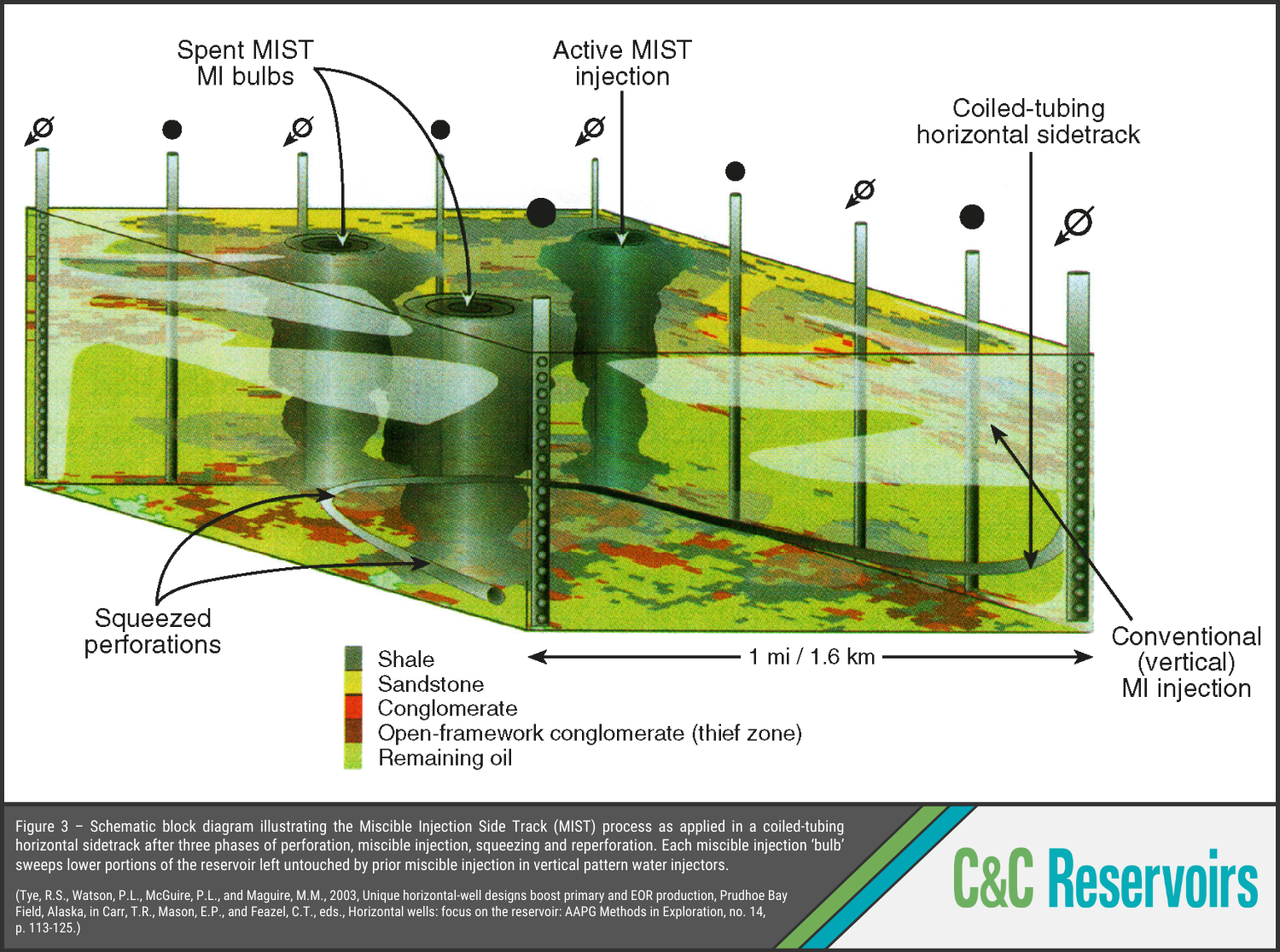

Other MI techniques have been tested at the field, including the Updip Zone 4 Miscible Injection (UZI) project, which recovered oil trapped in a narrow band between the waterflooded area and gravity-drainage zone. Miscible-injectant side track (MIST) treatments have been applied in depleted injection patterns to recover unswept oil overridden by injectant fronts. A horizontal sidetrack is drilled and perforated at its tip, from which MI is injected to push oil towards the producers. The perforations are then squeezed and the process is repeated closer to the kick-out point until the pattern area has been swept (Fig. 3). Using MIST, >1 MMBO have been recovered per horizontal sidetrack.