Introduction

Introduction

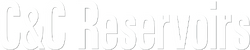

The Amal Field is situated in the eastern part of the Sirt Basin, Libya. It was discovered in 1959 and began producing in 1966. The field has an estimated STOIIP of 5 billion barrels, a very large productive area of 156,00 acres, and produces from a tight sandstone reservoir with an average permeability of one millidarcy. After more than 45 years of production, it has only recovered 18% of STOIIP (Figure 1).

Figure 1 – Production history curve (1966-2010) of the Amal Field.

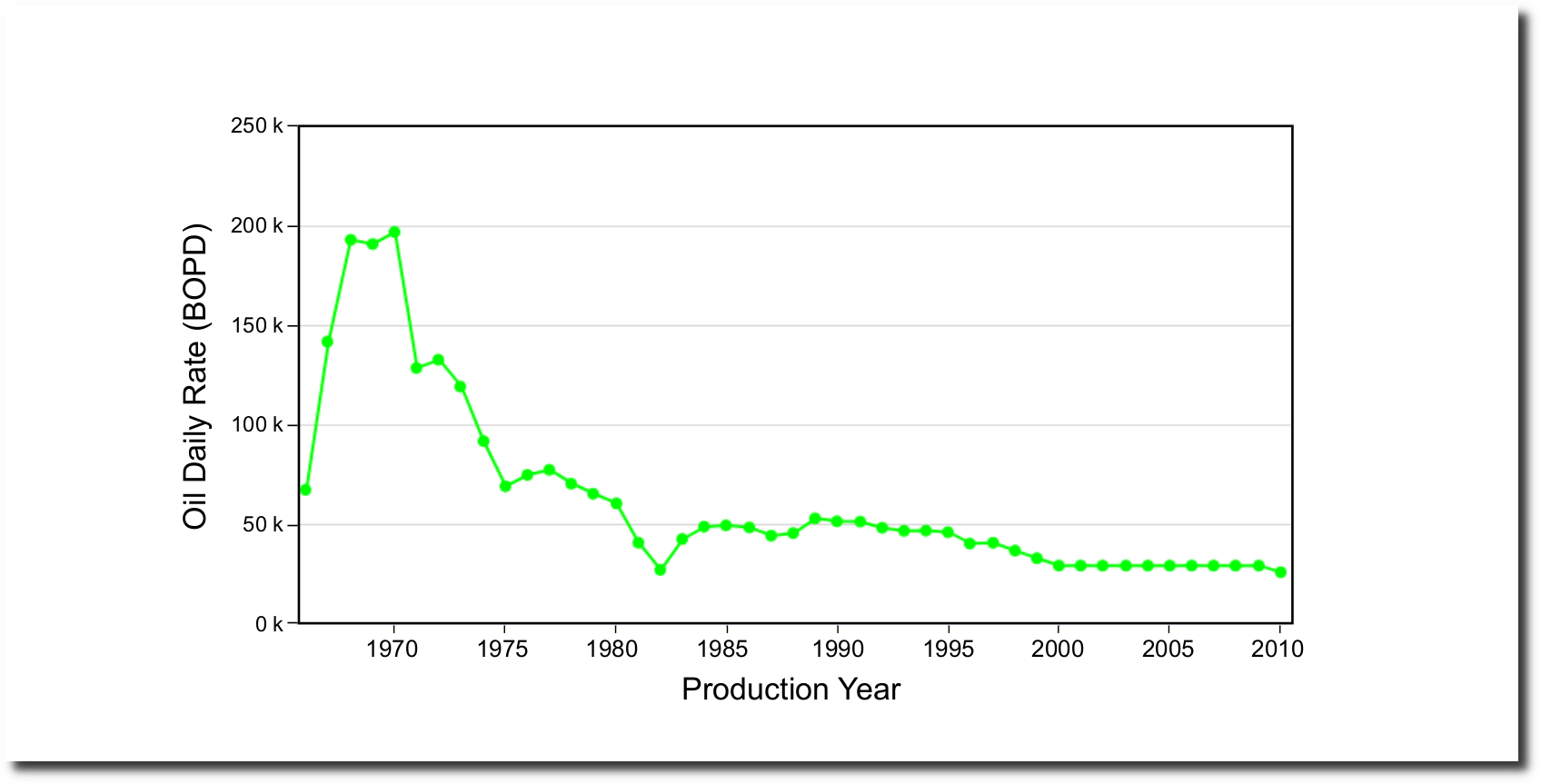

The DAKS™ Analogue Workflow (Figure 2) was used to review the Amal Field and benchmark its recovery factor against applicable global analogues to identify best practices from fields with more efficient recovery.

Defining Problems and Objectives

Defining Problems and Objectives

Given the production challenge of low reservoir permeability the key questions of this study are:

- What is the upside potential for Amal re-development?

- What ideas could be implemented from fields with similar production challenges?

Consistently Document Knowledge

Consistently Document Knowledge

Based on public domain data sources, both text and numeric parameters have been standardised and classified using the consistent rules defined by C&C Reservoir’s comprehensive classification scheme. This standardisation ensures that accurate comparisons can be drawn from directly comparable analogues contained within the DAKS™ knowledge base.

Choose Relevant Analogues

Choose Relevant Analogues

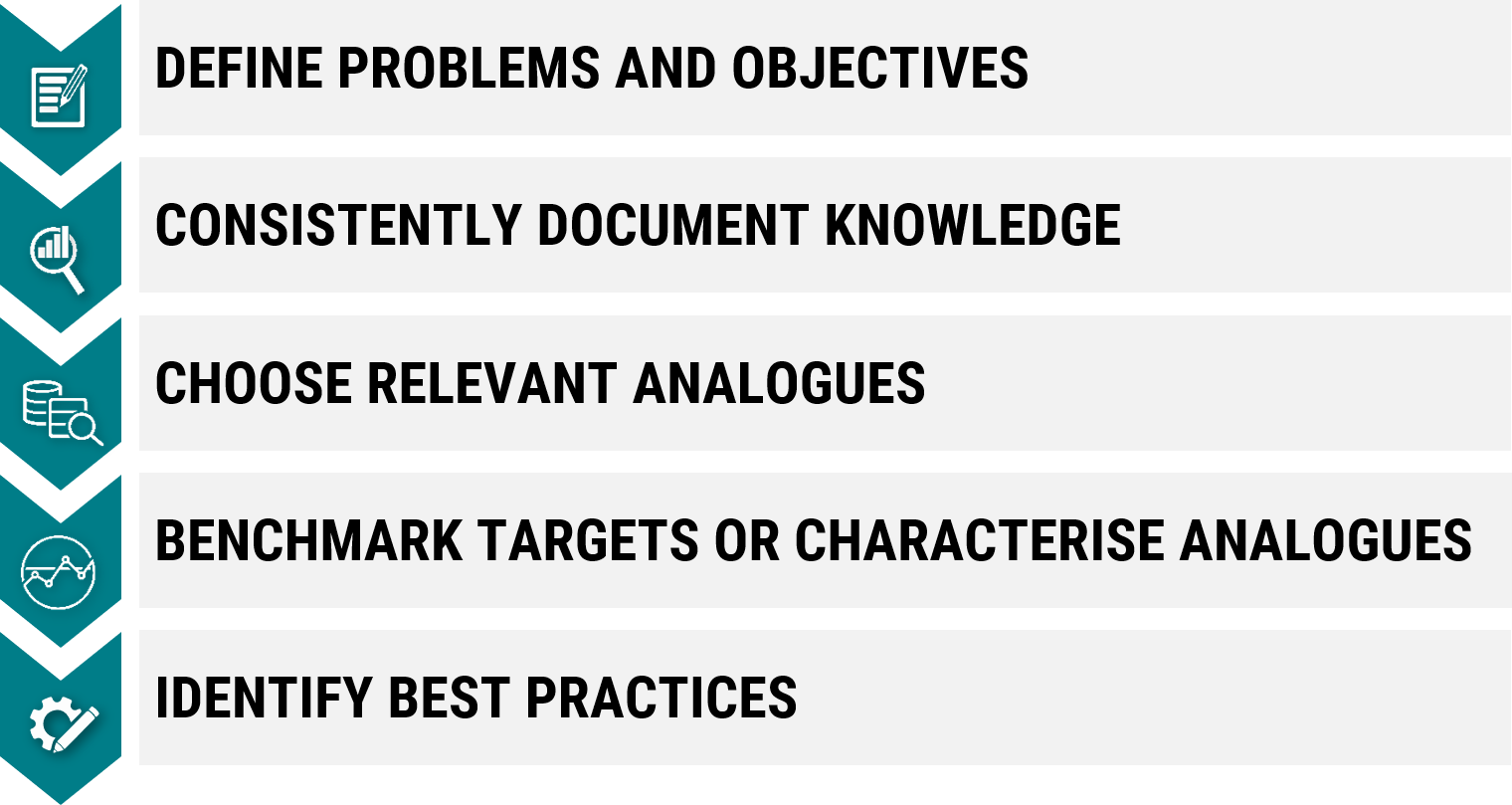

The following selection criteria (Table 1) has been used to identify appropriate analogues:

Table 1 – Analogue search matrix for the Amal redevelopment.

21 applicable global analogues were selected using the search criteria relevant to the Amal redevelopment challenges (Figure 3).

Figure 3 – Reservoir analogues for the Amal redevelopment opportunity.

Benchmark Targets and Characterise Analogues

Benchmark Targets and Characterise Analogues

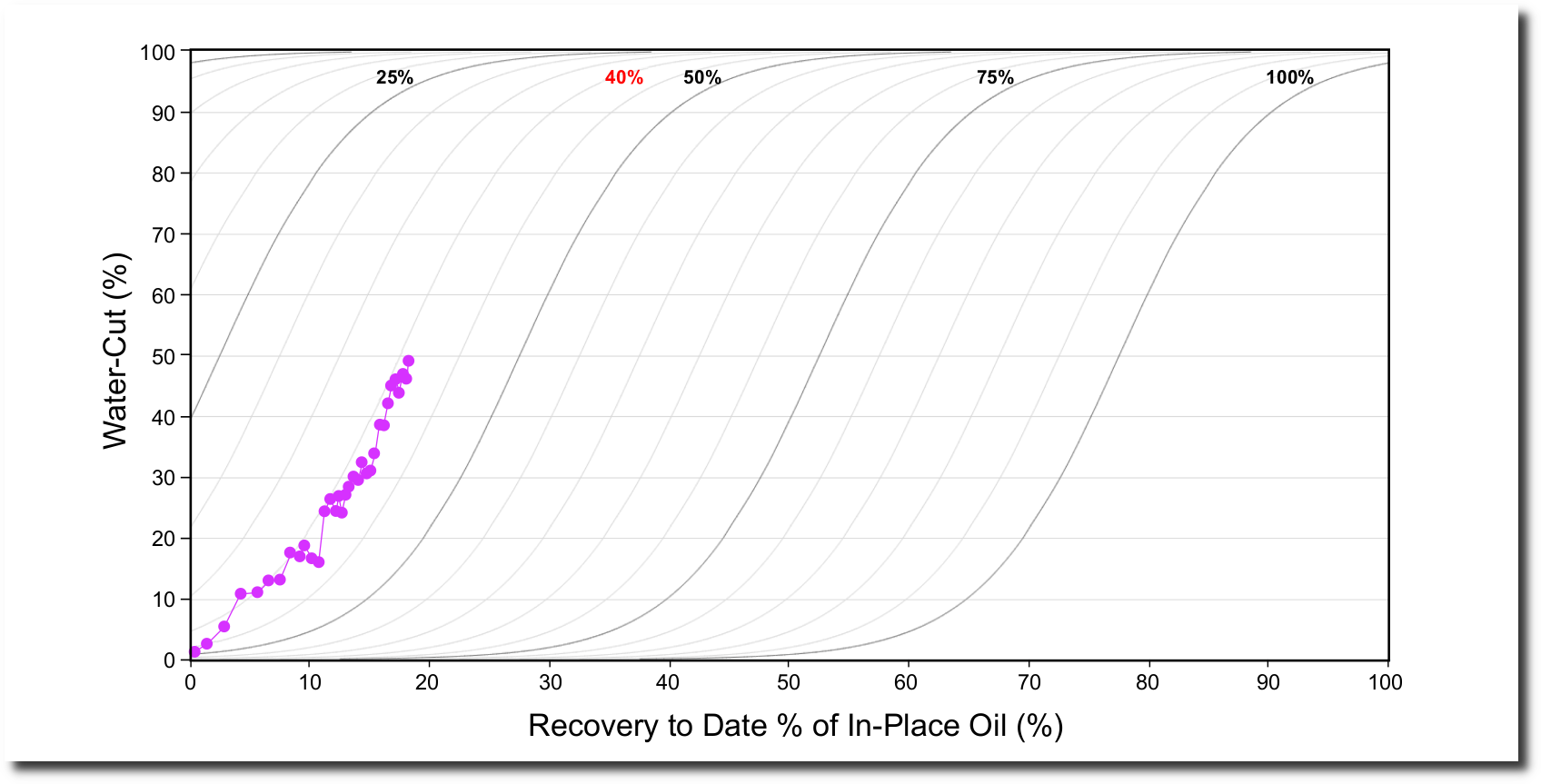

Analysis of recovery efficiency using the Empirical Recovery Chart, which describes the relationship between ultimate recovery, recovery to date and water-cut (cf. Tong, 1988), indicates an ultimate recovery factor of 40% should be possible for the Amal Field (Figure 4).

Figure 4 – Recovery efficiency against Empirical Recovery Chart (cf. Tong, 1988). Amal Field lies along 40% of the ultimate recovery trend, indicating the field has potential to recover 40% of STOIIP given its rock and fluid properties, drive mechanism and reservoir conditions.

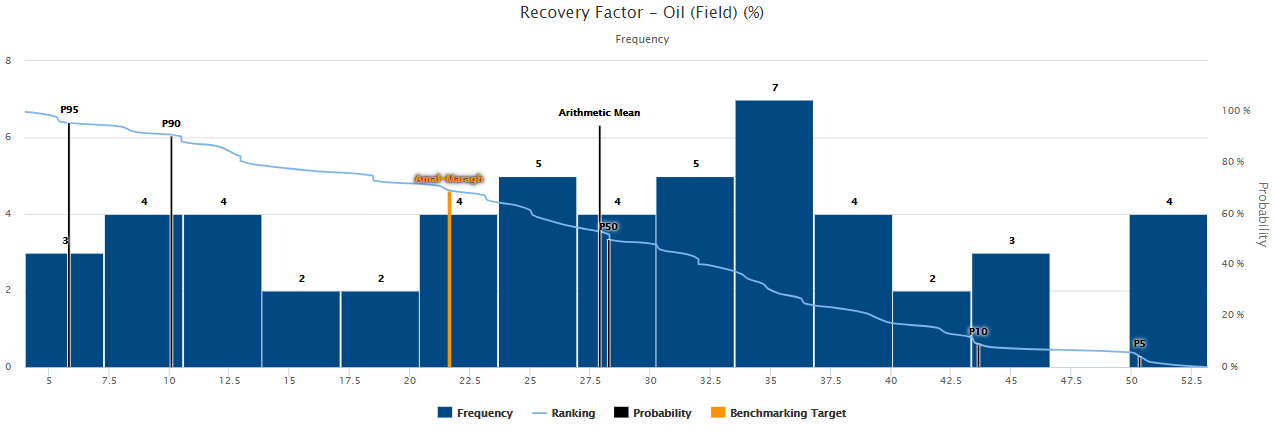

Benchmarking of Amal Field’s geologic and engineering parameters against applicable global analogues makes clear additional potential upside in recovery that can be realised with appropriate development techniques (Figure 5). Fields highlighted by the orange box will be analysed further to identify best practices that could be applied to Amal.

Figure 5 – Global analogues indicate the potential recovery factor upside at the Amal field.

Identify Best Practices

Identify Best Practices

Data from analogue fields with more than 30% ultimate recovery suggests several successful secondary methods (Table 2). These include continuous water injection, hydrocarbon gas injection and water-alternating gas (WAG) immiscible injection, and conformance improvement techniques, such as modifying injection pattern, profile modification and zonal injection. WAG miscible flood and CO2 miscible flood have also been successfully applied to several fields that have achieved higher recovery, such as Alpine, North Ward-Estes and Rangely fields. Reservoir management best practices from those fields with more than 30% ultimate recovery include horizontal wells, infill drilling, hydraulic fracturing, matrix acidisation, artificial lift, production optimisation and well treatment.

Table 2 – Reservoir management best practices for fields with >30% ultimate recovery factor

Conclusion

Conclusion

The poor reservoir quality and weak natural energy drive documented in the analogous reservoirs reinforces the need for improved recovery techniques and adoption of good reservoir management practices are critical to optimise the ultimate recovery of the low-permeability sandstone reservoirs. Analogue-based analysis allows the operator to evaluate the cost of improved recovery programs against the value of the potential remaining recoverable reserves. This gives the operator of Amal an accurate way to determine and contextualise the economic viability of any re-development opportunity.

References

References

Tong, X.Z., 1988, Statistical rules of natural and artificial water drive reservoirs, in Tong, X.Z. (editor) Analysis of Oil Well Production Performance and Reservoir Behavior: Publishing House of Documentation for Science and Technology (First Edition), Beijing, Chapter IV, p. 56-92.