The Athabasca Oil Sands

Analogue Spotlight

The Athabasca oil sands (Canada) ranks among the largest oil sand deposits in the world with the McMurray reservoir alone believed to have a STOIIP of 70.4 BBO and an EUR of 45.4 BBO (a recovery factor of 64.5%). Despite its excellent reservoir properties (30.5% average porosity and 7500 mD permeability), the oil occurs as bitumen, which is very heavy (6-10 °API), viscous (average 100,000 cP), immobile and hard to extract.

At Athabasca the oil sands crop out at the surface and have been commercially produced since 1967 via strip mining. This is only economically viable to a depth of 75 m, and >90% of the STOIIIP occurs below this threshold. As such, innovative in-situ techniques were required to effectively access the deeper deposits. Research led by the Alberta government, alongside academia and industry, concluded steam-assisted gravity drainage (SAGD) as the most effective technique in extracting this deeper, highly viscous heavy oil.

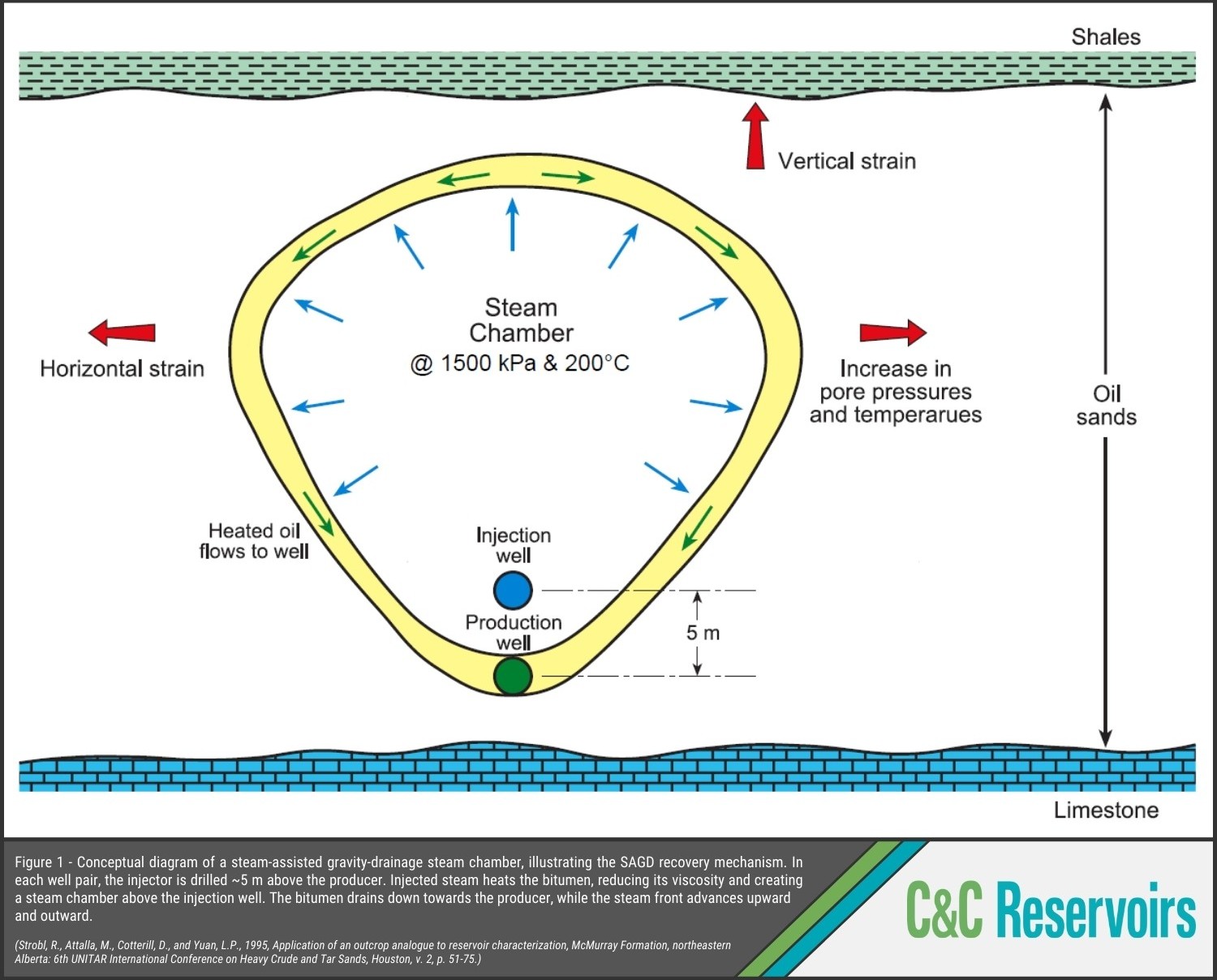

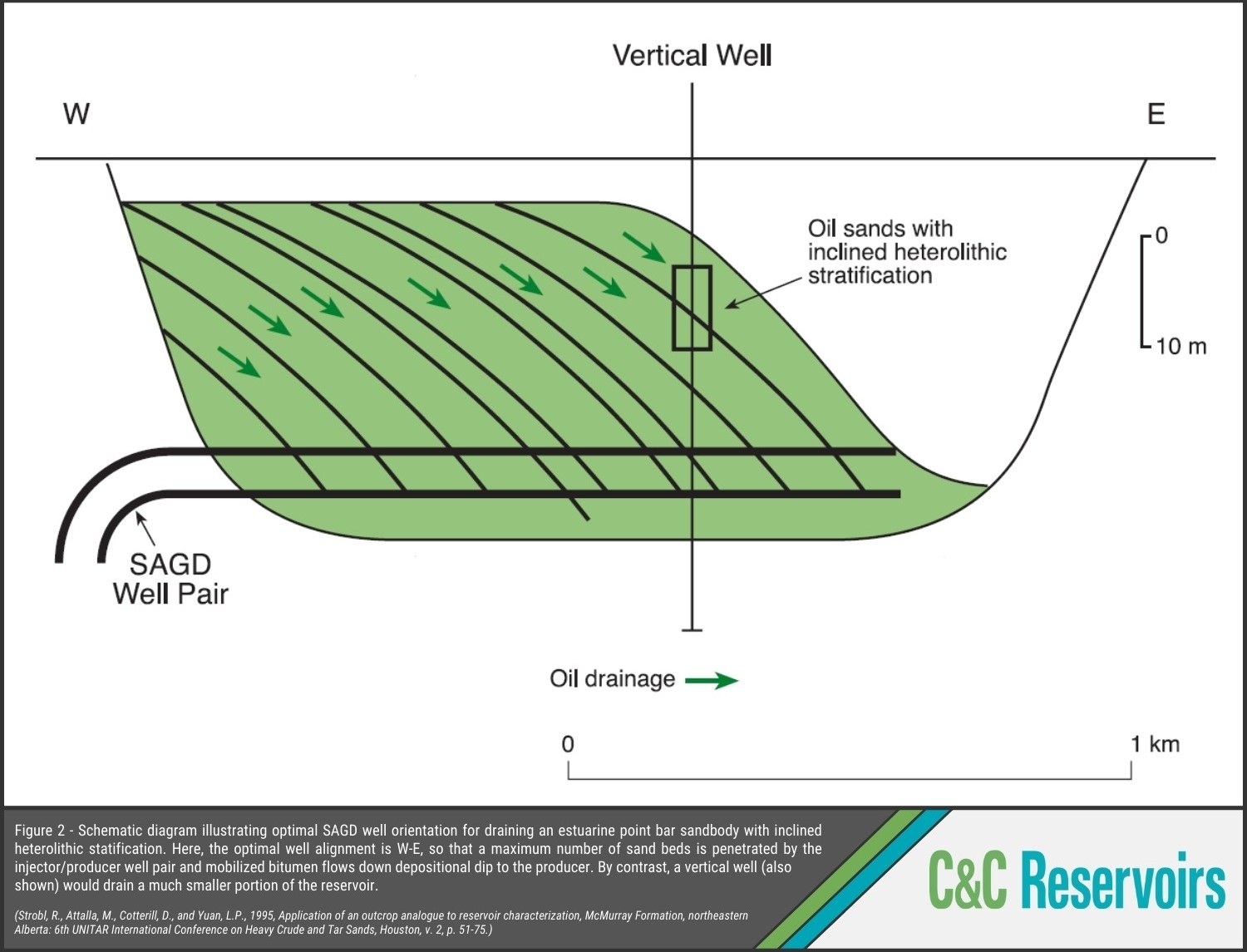

In 1999, after two phases of testing, SAGD was implemented in full, with pairs of wells being drilled from tunnels, with a horizontal injector placed 5 m above a producer. Steam released from the injector creates a chamber in which the bitumen is heated, reducing its viscosity to ~7 cP at 220 °C, allowing it to drain to the producer along with the steam condensate (Fig. 1). Much of the McMurray reservoir exhibits inclined heterolithic stratification. The optimal alignment of well pairs in these areas is therefore in the dip direction, allowing the maximum number of sand beds to be penetrated by injectors and producers (Fig. 2).

Since SAGD’s implementation, production has steadily increased from 37 MMB/day in 1999 to 1351 MMB/day in 2022. This technique proved incredibly successful with SAGD generally yielding recovery factors of 50-60%, although this number has been as high as 80%.