The McCully Gas Field

Analogue Spotlight

Located in New Brunswick, eastern Canada, McCully was Canada’s first unconventional gas field. To achieve commercial viability, hydraulic fracturing was essential. However, When water-based fracturing was proving ineffective in the McCully gas field, propane-based fracturing was tested as an alternative.

McCully features highly cemented lacustrine silty sandstones with low porosity (average of 6%) and permeability (average of 0.9 mD, with in-situ tests typically <0.1 mD). Prior to 2009, water-based fluids were used for fracturing with clean up flow continuing until well production fell below 13 BWPD. This caused delays and constrained gas throughput due to limitations in the water-handling facilities.

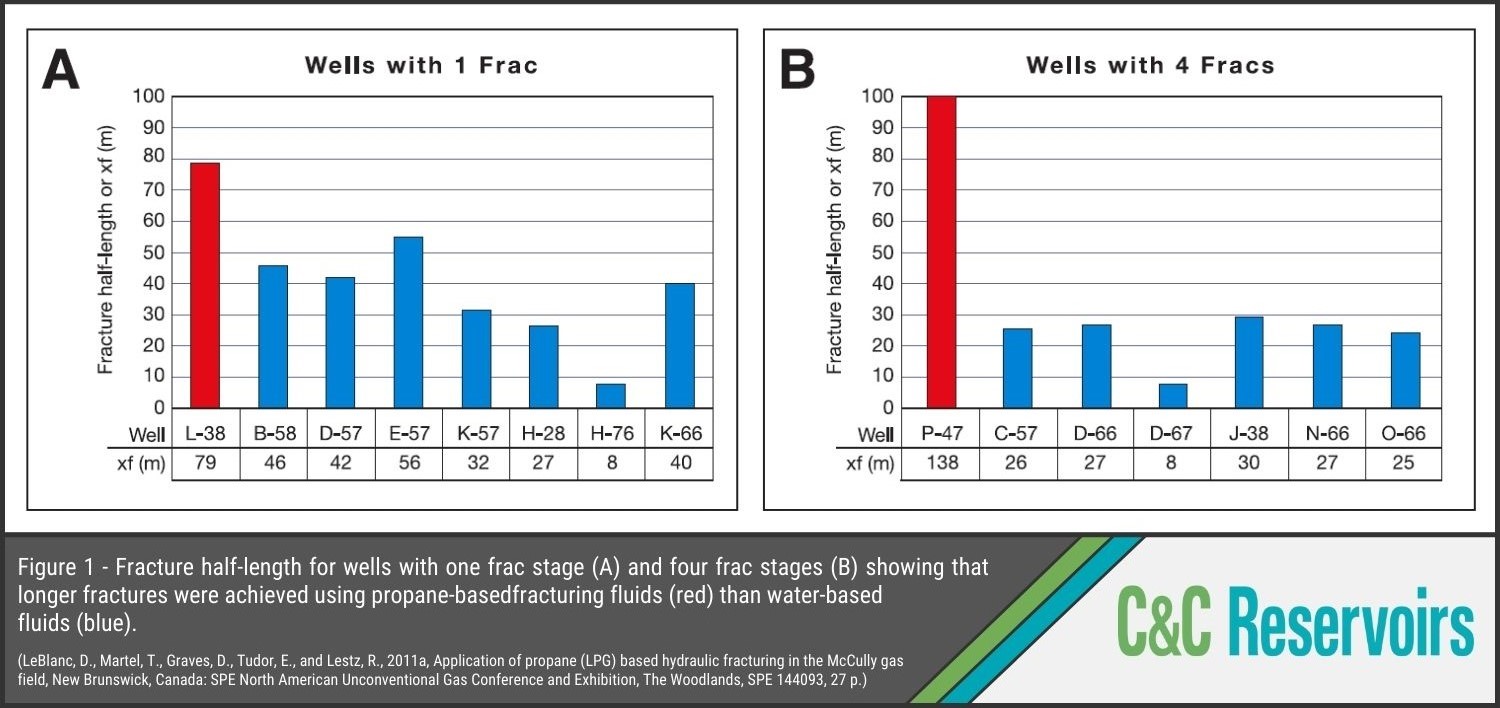

To address these challenges, three wells were stimulated using gelled propane-based fluids, aimed at reducing water production and enhancing fracture performance. The results were impressive: average well production reached 9 MMCF/day within four days, and 100% of the propane was recovered within 20 days – compared with 1000 days for water fracturing. In terms of productivity, the propane fracs achieved well IPs three times higher than water fracs. Additionally, gas from the reservoirs appeared at the surface almost immediately with propane, whereas water-based fracturing often required 5-20% of fluid recovery before any gas was observed. The effective fracture half-length was double that of water fracturing (Fig. 1).

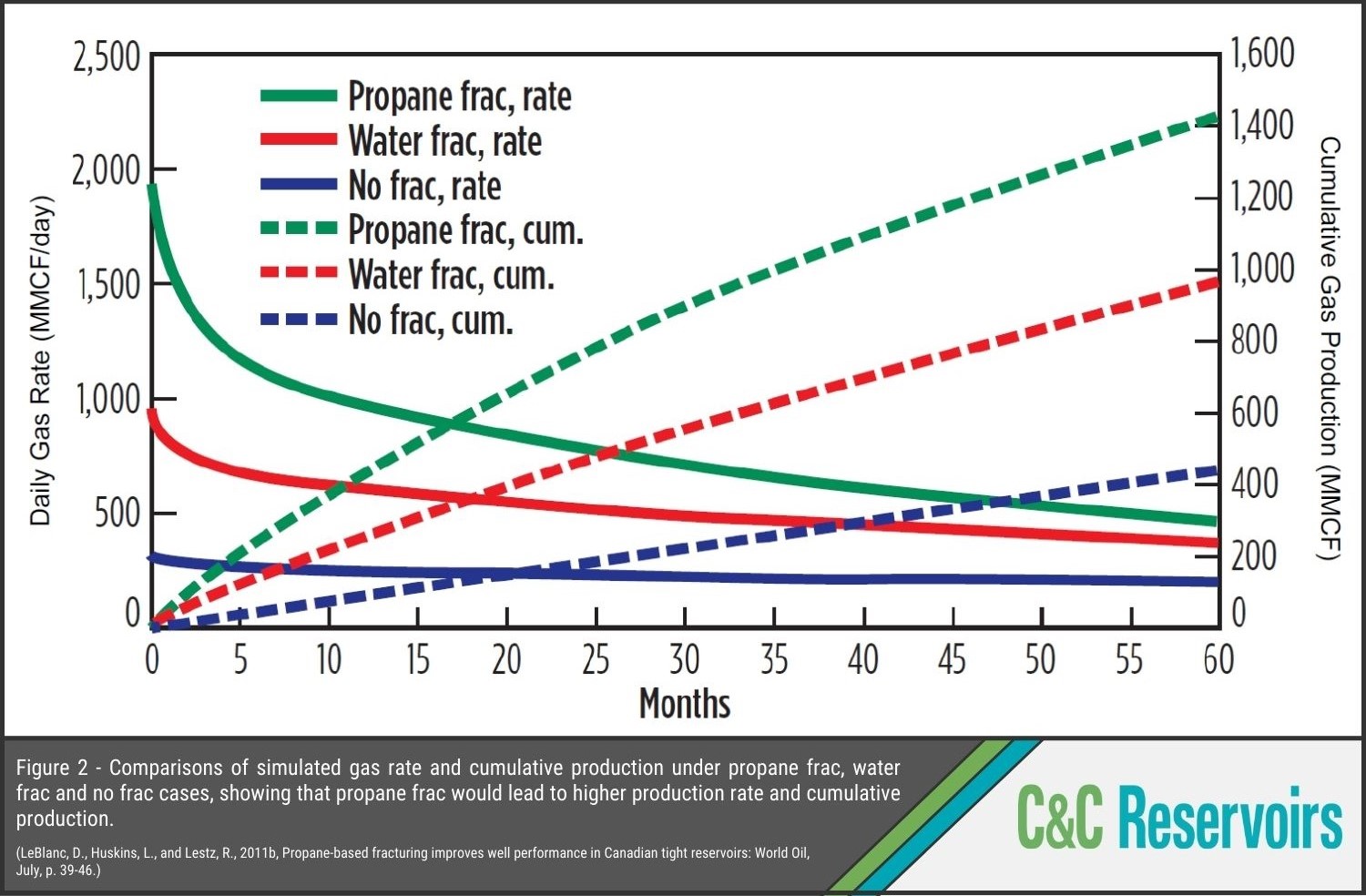

Ultimately, propane-based fluid was significantly more effective, with projections indicating higher sustained production. The only drawback was the higher cost of propane compared to water (Fig. 2).